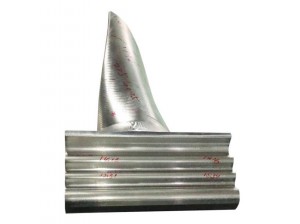

Top gas pressure recovery turbine blade

TRT BLADE

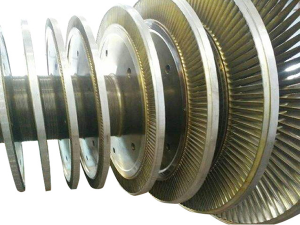

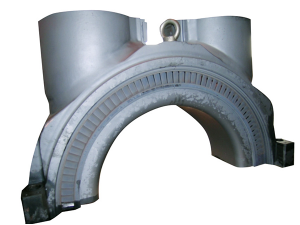

The power medium of TRT turbine generator unit is blast furnace gas. The turbine blade is the main part of the rotor system. The blade material is 2Cr13 and is subject to conditioning treatment. The blade is divided into two stages (i.e. two stages of moving blades and two stages of adjustable angle stationary blades), of which 26 are the first stage stationary blades and 30 are the second stage stationary blades; There are 27 first stage moving blades and 27 second stage moving blades. The working speed of the rotor is 3000 rpm (the first critical speed is designed as 1800 rpm; the second critical speed is designed as 6400 rpm).

Although most of the furnace dust can be removed after dedusting, there is still a certain amount of furnace dust, water vapor and a variety of acid gases generated due to impure blast furnace raw materials, such as H2S, HCL, CO2, etc. in the gas phase medium. Due to the expansion of the unit, the temperature is gradually reduced, and the acidic gas is dissolved in the condensate, which causes acidic water to adhere to the surfaces of blades, shells, deflectors and other components for a long time. In addition, the chlorine ions in the gas under high temperature are released, which causes excessive corrosion of the blades; At the same time, due to the high speed

Under the condition of long-term operation with blast furnace dust, particles will continuously generate cutting friction and direct friction on the blade surface that has been corroded and has no strength, resulting in too fast damage to the blade. Once the blade is damaged, the direct impact on the unit is low efficiency and large vibration.

As the blade not only has high replacement cost, but also plays a crucial role in the safe operation and continuous production of the unit, the enterprise attaches great importance to it and adopts corresponding means to repair and protect it, such as laser cladding repair, anti-corrosion coating repair and protection, metal powder spraying pre protection, etc., which have certain effects.