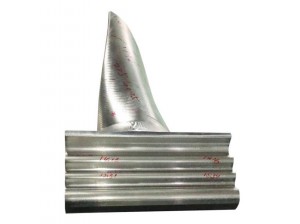

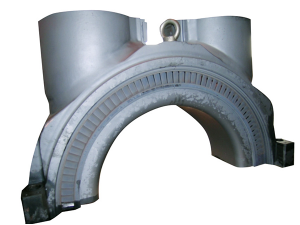

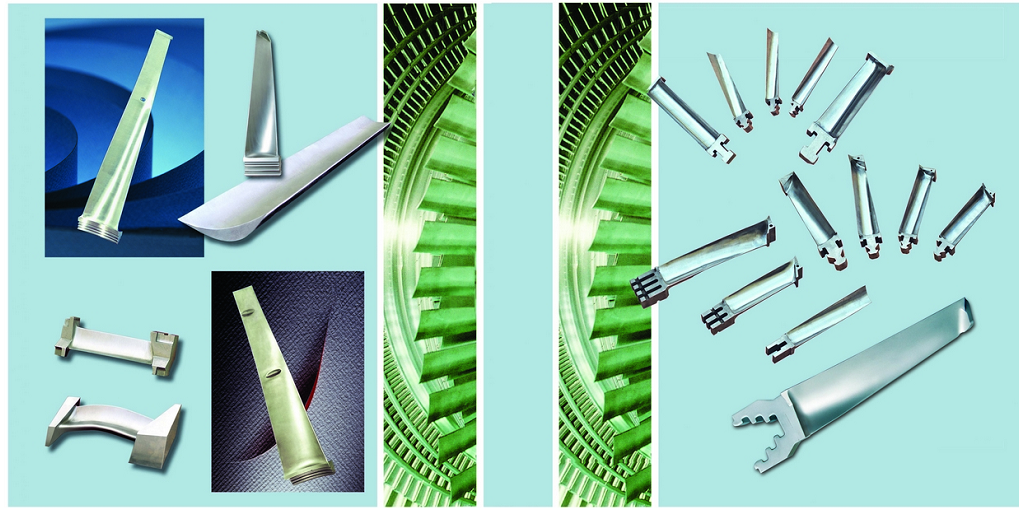

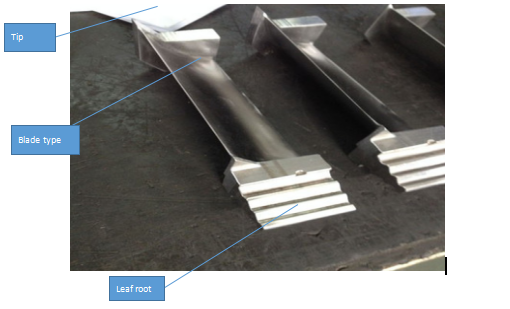

Turbine blade under 600WM (inclusive)

Product Description

It can withstand high temperature, high pressure, huge centrifugal force, steam force, steam exciting force, corrosion and vibration, and water droplet erosion in wet steam area under extremely harsh conditions

effect. Its aerodynamic performance, processing geometry, surface roughness, installation clearance, operating conditions, scaling and other factors all affect the efficiency and output of the turbine; Its structural design, vibration, strength and operation mode have a decisive impact on the safety and reliability of the unit.

The turbine blades are subjected to the action of high-temperature and high-pressure steam, and bear a large bending moment in the work. The moving blades in high-speed operation also bear a high centrifugal force; The blades in the wet steam area, especially the last stage, have to withstand electrochemical corrosion and water droplet erosion, and the moving blades also have to withstand very complex excitation forces. Therefore, the blade steel shall meet the following requirements:

1. Have sufficient mechanical properties and creep resistance at room temperature and high temperature;

2. High anti vibration attenuation capability;

3. High tissue stability;

4. Good corrosion resistance and erosion resistance;

5. Good process performance.

The company is a professional manufacturer of blades. At this stage, it is mainly capable of manufacturing the moving and stationary blades of steam turbines of units below 65mw (including laser, cladding, spraying and other special processes). The procurement of blade raw materials has formed strategic cooperation with Fushun Special Steel, Liuhe and other well-known large steel plants in China. The company has 3 imported turning and milling compound five axis machining centers, 4 imported five axis linkage machining centers, 4 full-automatic CNC lathes, 3 hexcon three coordinate detectors, GOM scanners and several auxiliary testing equipment. The company has a strong technical team and has rich experience in blade design, reverse engineering, modeling, programming and post-processing.

The company has a very good quality control team and excellent testing technology, advanced manufacturing and testing equipment and rich experienced technical team. The company has a good reputation and has long-term good cooperation with well-known manufacturers at home and abroad.