Products

-

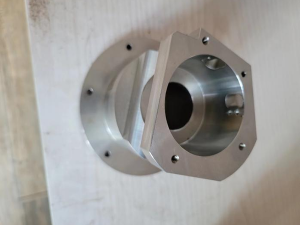

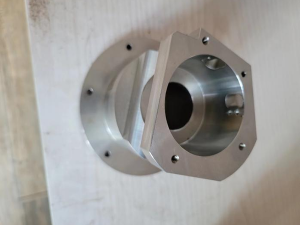

Gas turbine diffuser and cover plate

Diffuser can be divided into vaned diffuser and vaneless diffuser. Its working principle is to convert velocity energy into pressure energy by making use of the different cross-sectional areas of flow passage. Vane diffuser restricts the flow direction of air flow through the shape of blade, thus shortening the overall structure size of diffuser channel. In axial compressors, vaneless diffusers are usually used after the last stage to recover the velocity energy of air flow. Of course, a similar diffuser will be used at the outlet of the turbine expander.

-

Flagship product fan wheel of centrifugal fan

Centrifugal wind wheel refers to the wind wheel with axial air inlet and radial air outlet, which uses centrifugal force (depending on speed and outer diameter) to do work to increase air pressure.

-

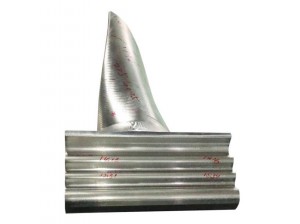

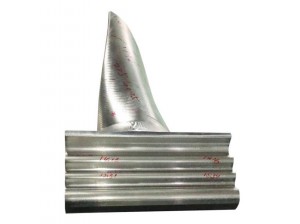

Gas turbine custom superalloy turbine blades

As we all know, blades in gas turbines are the “heart” of turbomachinery and the most important parts in turbomachinery. Turbine is a kind of rotating fluid power machinery, which directly plays the role of transforming the heat energy of steam or gas into mechanical energy. Blades generally work under high temperature, high pressure and corrosive medium. The moving blades also rotate at a high speed. In large steam turbines, the linear velocity at the top of the blade has exceeded 600m/s, so the blade also bears great centrifugal stress. The number of blades is not only large, but also the shape is complex, and the processing requirements are strict; The processing

-

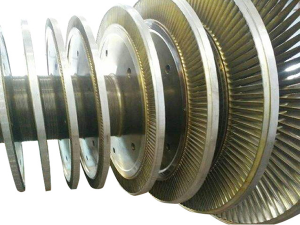

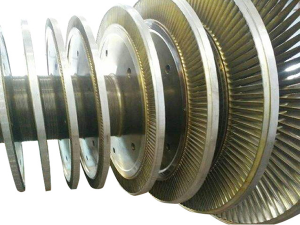

Top gas pressure recovery turbine blade

TRT is the abbreviation of Top Gas Pressure Recovery Turbine, which is translated into “Top Pressure Recovery Turbine Power Generation Device of Blast Furnace” in Chinese. It is a device that uses the top pressure of blast furnace gas to generate electricity. This technology uses the high pressure gas pressure to drive the turbine rotor of TRT to do rotary work, and the mechanical energy is converted into electrical energy by the generator connected in series with it.

-

Turbine blade under 600WM (inclusive)

The turbine blade is the key part of the turbine, and also one of the most delicate and important parts. It is mainly composed of blade root, blade profile and blade tip.

-

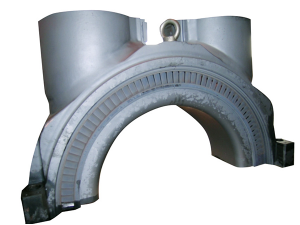

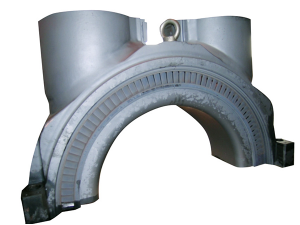

Turbine stationary blade diaphragm

Purpose of steam turbine diaphragm: it is used to fix the stationary blades and form the partition walls at all levels of the steam turbine.

-

Turbine blower & Axial compressor blade

Wind turbine blade (wheel) is one of the core components of wind power equipment, accounting for about 15% – 20% of the total cost of the equipment. Its design will directly affect the performance and benefits of the equipment.

Fan blades are commonly used in fans, turbine blowers, roots blowers and turbine compressors. They are divided into eight categories: centrifugal compressors, axial-flow compressors, reciprocating compressors, centrifugal blowers, roots blowers, centrifugal fans, axial-flow fans and ye’s blowers.

-

Turbine reinforcement and enclosure

The main function of the nozzle group in the steam turbine is to make the steam flow on the blades of the rotor wall through the guide of the nozzle group.

-

Wholesale price of high-quality steam turbine nozzle set

The main function of the nozzle group in the steam turbine is to make the steam flow on the blades of the rotor wall through the guide of the nozzle group.

-

General metal workpiece processing

Mechanical cold working usually refers to the cutting method of removing materials by workers operating the machine tool, that is, cutting tools are used to remove excess metal layers from metal materials or workpieces, so that workpieces can obtain a processing method with certain shape, dimensional accuracy and surface roughness. Such as turning, drilling, milling, planing, grinding, broaching, etc.